Product Introduction

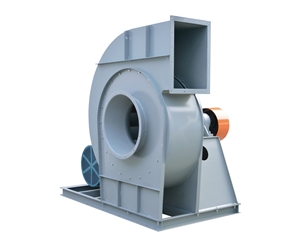

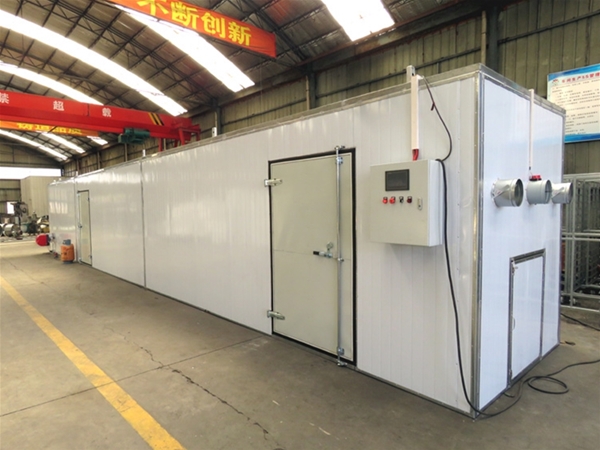

Air source heat pump dryer,It uses the principle of reverse Carnot cycle to absorb heat energy from the air, and the heat exchange medium is pumped by a hot air energy pump device(R134AConvert into high-temperature thermal energy (with temperatures reaching up to)80-115℃)And through the heat exchanger of the drying equipment, the temperature of the drying room is increased, causing the moisture in the materials to vaporize and evaporate. The evaporated water vapor is discharged by the dehumidification system to achieve the purpose of drying the materials. Compared to traditional heating drying methods. Air source heat pump drying has two unparalleled advantages:

oneDuring the drying process, the air source heat pump dryer can recycle and actively dehumidify the latent heat in the hot and humid air discharged from the drying room, greatly improving the drying efficiency and further reducing energy consumption. The drying energy consumption is only equivalent to that of electric heating1/4about.

twoAccording to the drying process of different materials, the air source heat pump dryer can control the temperature at Celsius20-80Between degrees, the environmental humidity can also be controlled as needed.

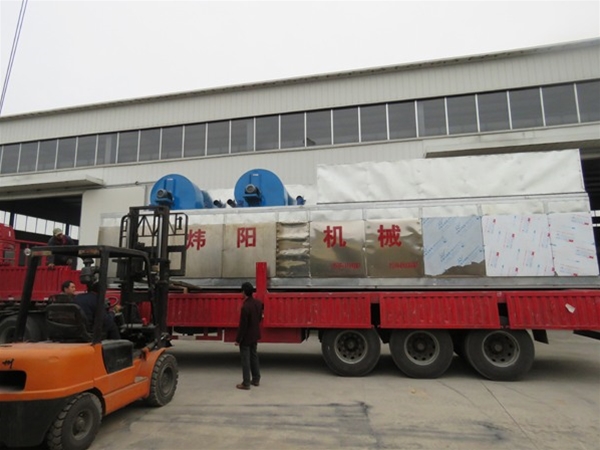

Air source heat pump dryers, with their advantages of energy saving, safety and pollution-free, have begun to be applied in agriculture, industry, textile industry and other fields. In many regions of China, such as Qingdao, the application of air source energy-saving equipment has even been promotedThe energy-saving subsidies and air source heat pump drying are gradually replacing traditional boilers, electric baking and other methods, becoming the backbone of the drying industry.

Product performance parameters:

Drying products:

|  |  |

| Spicy drying | Drying of seafood and fish | Drying of traditional Chinese medicinal materials |

|  |  |

| Drying of shiitake mushrooms | Noodles drying | Vegetable drying |