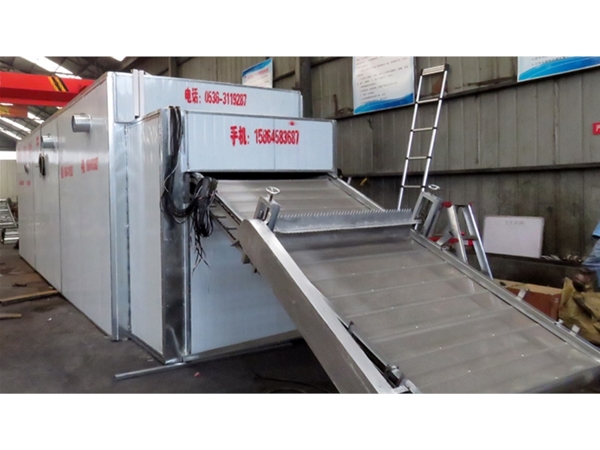

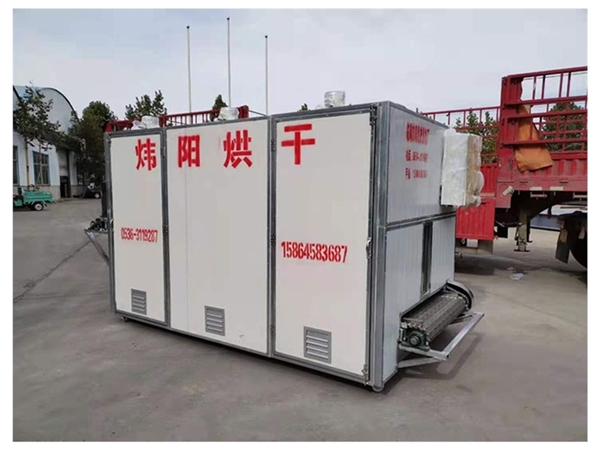

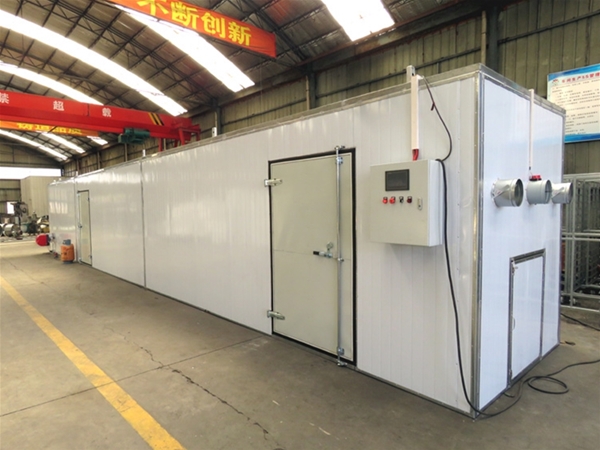

Long rod hot cutting furnace

Technical parameters of fully automatic multi long rod hot cutting furnace

The fully automatic multi long rod hot cutting furnace is a new type of production equipment that integrates thermal, mechanical, automation control, hydraulic, photoelectric, and temperature measurement. It is composed of aluminum rod feeding transmission and conveying frame, furnace body, hot cutting machine, and electrical control.

1�、 Product Design Basis:

| Serial number | Product Name | model | Squeezing machine ton Position and direction | Aluminum rod diameter/length | Number of stored rods in the furnace | Hot shear force |

| one | Long rod hot cutting furnace | LRJ-150 | 1200T | Φ150×6000mm | 12 pieces | 80T |

2、 working principle:

Store the long aluminum bars of the melted and cast ladle on the storage rack first, and use the rolling rod mechanism to feed the long bars one by one into the heating furnace for heating. During this heating process, the bar material will flip and move. After heating each bar for no less than 2 hours, the long bars are gradually fed into the hot shear machine for sizing under the drive of the conveying rod mechanism, and the aluminum bars are supported by a fixed blade seat. Under the action of the shearing oil cylinder, the movable blade seat is pushed downwards to cut the aluminum bars, and then the top rod oil cylinder is used to fix the aluminum bars outside the fixed blade seat.

3��、 Main technical skills

| Serial number | name | Main technical parameters for adapting 1200T extruder |

| one | Hydraulic station power | 18.5kw |

| two | Circulating fan power | 11.5kw |

| three | heating temperature | 480℃—550℃ |

| four | Starting heating time | 3h—4h |

| five | External dimensions of furnace body | |

| six | Aluminum rod temperature difference | ±10℃ |

4���、 Main configuration parameters:

1 & nbsp;& nbsp;Shearing machine

| Serial number | name | technical parameter |

| one | Cut the main steel | Φ300 |

| two | Other oil cylinders | Its 8 sets |

| three | Rod insertion and extraction mechanism | Self aligning bearing seat, chain driven roller |

| four | scissors | Use H13 mold steel with a hardness of HR6-48 |

| five | Fixed length mechanism | Determine the cutting length according to production needs, adjustable from 300 to 800mm |

2 furnace bodies

| Serial number | name | technical parameter |

| one | Furnace shell | Welding of steel sections, using 3mm steel plates for the shell welding |

| two | Insulation layer | 300mm thick fiberglass insulation cotton |

| three | Inside the protective chamber | Use 304 stainless steel plate with 2mm thickness and thermal expansion joint reserved |

| four | Circulating air duct | Use 304 stainless steel plate with a thickness of 2mm to make air distribution, manually adjust the air door |

| five | Flipping mechanism | Hydraulic flipping mechanism, specially designed upper and lower cast iron sleeves to ensure smooth rod movement |

| six | Roll bar rack | Slanted automatic flipping bar material rack, aluminum bars gradually roll during the process of entering the furnace |

| seven | Rod delivery mechanism | Axis rotation |

| eight | Testing rod mechanism | Three sets of measuring rod mechanisms achieve highly accurate rod picking, automatic rod moving, and rod feeding |

| nine | Air cooling system | 550W centrifugal fan for cooling the transmission shaft and bearings |

| ten | Entrance and exit furnace door | Cylinder automatic door opening and closing |

| eleven | Repair port | The furnace openings at the front and back of the furnace can be used to observe the operation inside the furnace, which is convenient for maintenance |

2 & nbsp;& nbsp;Fuel chamber

| Serial number | name | technical parameter |

| one | Fuel chamber structure | Welding of steel sections, using 3mm steel plates for the shell welding |

| two | Combustion tube | 310S stainless steel cylinder, 4mm thick, installed at the air outlet of the fan to prevent the fuel burning cylinder from burning out |

| three | Fire Mouth | Make a horn mouth with 310S stainless steel and fix it to the combustion pipe mouth with flanges and stainless steel screws |

| four | High temperature fan | The casing is 2Cr13, the impeller and shaft are 304S, and the cooling system of the high-temperature fan adopts water cooling, which is conducive to enhancing the effect of energy conservation and emission reduction |

| name | Main technical parameters for adapting 1200T extruder |

| Entering the club, marrying the club | 1.5kw |

| Pick up the length of the aluminum rod | 300~800mm |

| Vertical accuracy of the cut aluminum rod | ±2mm |

| Fuel | Gas |

| Consumption amount | Gas costs around 900 per day/12 hours |

| Temperature measurement method | 3 sets of thermocouples |

| electrical system | Mitsubishi PCL Control |

| Hydraulic system | Guangye double blade pump, hydraulic valve |

| Rod insertion method | Backward stick style |